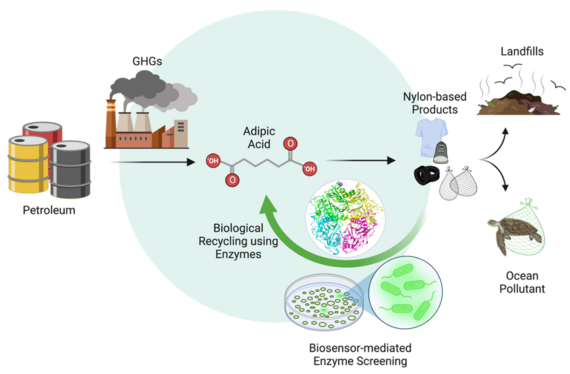

Nylon-based waste, like textiles, carpets, tires, and fishing nets, which is often found in landfills and oceans, releases considerable amounts of the greenhouse gas (GHG) nitrous oxide into the environment. Degrading or depolymerizing nylon using biocatalysts could pave the way to reducing waste and enabling more efficient recycling of nylon into new products without emitting nitrous oxide.

As part of the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE) consortium and the Agile BioFoundry, scientists at Los Alamos National Laboratory (LANL) have developed a biosensing technology that can help address the problem of plastic waste made from nylon-66, a common, very tough nylon made of a polymer building block called adipic acid (ADA). Unfortunately, the petroleum-based production of ADA releases GHG nitrous oxide into the environment.

In research published in ACS Synthetic Biology, this new biosensor technology not only found the candidate biocatalysts – typically enzymes or whole cell microbes – required to degrade nylon into its ADA building blocks, but also detected the ADA molecules needed to confirm the biocatalyst process worked.

“We are actively using the novel biosensor technology to discover and engineer efficient nylon-degrading enzymes for “green” recycling of the building blocks or upcycling into bioadvantaged products,” said LANL, BOTTLE and Agile BioFoundry biochemist Dr. Taraka Dale, who led the R&D team for biosensor development.

Read more about this U.S. Department of Energy Bioenergy Technologies Office (BETO) and Advanced Materials & Manufacturing Technologies Office – funded research on BETO’s Bioprose: Bioenergy R&D blog.