High Throughput Screening

Quantitatively survey libraries of engineered strains

Targeted proteomics

Targeted proteomics is a mass spectrometry-based protein quantification technique that can accurately quantify protein abundance, stoichiometry of protein isoforms and protein post-translational modifications. This capability can help determine pathway bottlenecks, compare enzyme homologs for specific enzyme steps, and track dynamic regulation of protein levels in engineered microbes.

Instrumentation:

- Agilent 1290HPLC-6460QqQ LC-MS systems

Applications:

- Identifying protein-associated bottlenecks, resulting in improved final product levels

- Quantifying protein levels for genetic tool development studies

- Characterization and quantification of stable post-translational modifications for engineered microbes

Biocatalyst optimization

We use a microfluidic platform to identify improved and/or missing catalysts in production pathways. This approach is compatible with aerobic or anaerobic enzyme screening (in vivo or cell-free). The system can utilize a wide-array of reporter systems to rank the efficiency of pathways, including transcription-factor-based biosensors, FRET biosensors, or enzyme-linked sensors.

Once candidate genes have been identified, variants are synthesized using rational design/directed evolution approaches. Appropriate sensors are linked to monitor reaction improvements, and in-depth characterization of candidate enzymes is carried out in vitro and in target-host systems.

This pairing of microfluidics and biosensor design/engineering for molecular adaptation in the Agile BioFoundry can only be found in a few unique research environments.

Thermostability Screening

Our THERMAS Technology is a rapid method to screen large number of variants of an enzyme with engineered stabilizing mutations by directly using a thermophile as a chassis for screening. Expression of the variants as a fusion with a custom-engineered anaerobic fluorescent reporter aids high throughput selection of variants based on the whole cell fluorescence from the colonies on a petri dish. This technology is generalizable to any enzyme of interest and can be performed on libraries in the range of 10^3- 10^5 sequence diversity.

Microbioreactor Systems and Sampling Platform

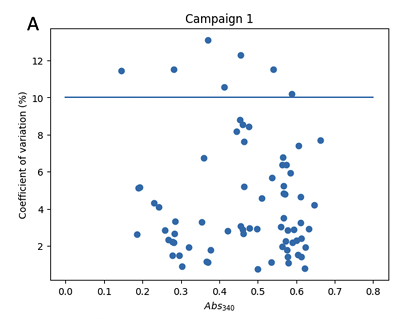

Our high-throughput systems for biological engineering and process development can be used to perform process optimization and strain screening, ensure data quality and reproducibility, and gain valuable insights before scaling up to bioreactors.

BioLector

A high-throughput cultivation system based on microtiter plates with on-line continuous monitoring of cell density, dissolved oxygen (DO), pH, and fluorescence.

RoboLector

A liquid handling system that can be utilized for automated sampling, bolus feeding, and discontinuous pH adjustments in conjunction with the BioLector instrument for fed batch experiments.

BioLector Pro

A cultivation system that uses microtiter plates with microfluidic systems that allow for continuous individual pH and feeding control, in addition to on-line monitoring of cell density, DO, and fluorescence.

USE CASE

The BioLector microbioreactor system was utilized during the “Build” and “Test” phases of the Design-Build-Test-Learn (DBTL) cycle to optimize media compositions for enhancing compound titers in specific bacterial strains.

Production data fed into machine learning algorithms identified media components that improved titers. The collected data was used to predict and refine new media compositions. Through iterative cycles on the BioLector system, compound titers were successfully increased by 148%