As innovations in synthetic biology, genome editing, and DNA synthesis have accelerated biomanufacturing research over the past few decades, demand for faster analytical tools for molecular phenotypic analysis has increased. These tools measure proteins and metabolites, the small molecules produced by biological systems. Such tools provide critical insights into bioprocesses that produce sustainable fuels and chemicals from renewable sources. These tools must match the rapid pace of genetic engineering, to continue the pace of innovation in biomanufacturing research.

A new workflow developed by researchers at the Agile BioFoundry (ABF), a U.S. Department of Energy Bioenergy Technologies Office-funded consortium of national laboratories, and Agilent Research Laboratories (Agilent) addresses this need. The workflow combines state-of-the-art analytical technologies with a machine learning-based algorithm, providing a faster and more powerful way to process data that could accelerate the Design-Build-Test-Learn framework, a bio-engineering cycle used to improve biomanufacturing research and processes.

Speeding up this bio-engineering cycle could ultimately speed up biomanufacturing research. One of the biggest barriers to accomplishing this is the ability to improve the Learn step of the cycle, which involves using data to improve future cycles. However, improvements to the Learn step can only happen if large amounts of high-quality data are gathered in the Test step of the cycle.

The consortium teams set out to create a workflow that could generate high-quality analytical Test data that could feed into the Learn step. The workflow they developed includes several components. The first is a high-throughput analytical method developed in collaboration with Agilent. This method enables a threefold reduction in sample analysis time (compared to previous conventional approaches) by using optimized liquid chromatography conditions.

The second component is the Automated Method Selection Software tool, which predicts the best liquid chromatography method to use for analyzing new molecules of interest. Lastly, a novel algorithm called PeakDecoder processes multi-dimensional metabolite data and automatically calculates errors in metabolite identification. Together, these components form a workflow that quickly tests strains generated by high-throughput engineering workflows.

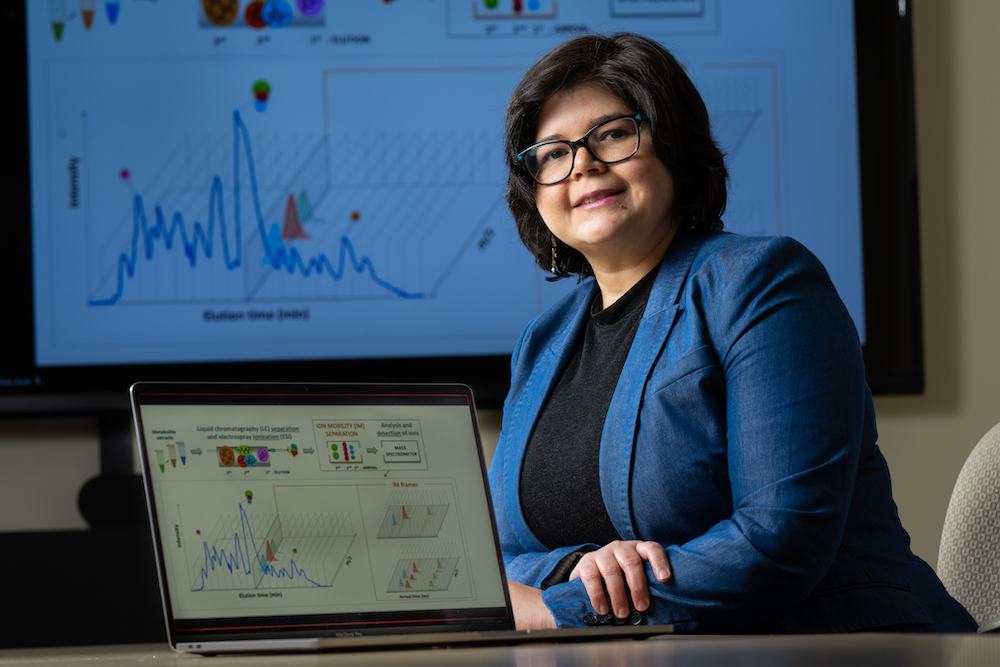

To test its effectiveness, the researchers used the workflow to study metabolites of various strains of microorganisms engineered by ABF. The microorganisms they tested all have the capacity to make various bioproducts, such as polymer and diesel fuel precursors. Using their workflow, the researchers were able to interpret 2,683 metabolite features across 116 microbial samples. “This workflow allows for fast analysis of current and new metabolites of interest,” said Kristin Burnum-Johnson, a biochemist in the ABF. “This capability is broadly useful, beyond the Agile BioFoundry, in a wide range of environmental and biological metabolomics research.”

The researchers see the PeakDecoder algorithm as a stepping stone towards creating an automated data-gathering pipeline. “This could potentially replace traditional tools that require human input with artificial intelligence-based methods,” said Aivett Bilbao, an ABF computational scientist who created the PeakDecoder algorithm. The team is already working on leveraging state-of-the-art artificial intelligence methods like computer vision used in other fields. Bilbao said the next version of PeakDecoder will have improved automation and identification performance and will be more applicable to other types of molecular profiling, including proteomics workflows.

Alex Apffel, a senior research scientist at Agilent, said this collaboration helped his team better understand their customers. “One of the benefits of collaborating on a multi-site collaboration like this was that we learned a lot about what our customers’ perceptions and problems are,” he said. “We don’t always get to see that kind of information, so that’s very useful to us.”

Apffel added he was impressed with what the teams were able to accomplish despite being distributed across various locations. “The Agile BioFoundry was kind of visionary in understanding that you don’t have to be in the same place to work efficiently with each other — even when there are physical materials that need to be exchanged, not just information,” he said.