The Agile BioFoundry (ABF) invites industry partners to enter collaborations (Strategic Core Industry Partnerships) utilizing biomanufacturing tools and capabilities developed or optimized by ABF consortia labs (see below). From these partnerships, companies can leverage cutting-edge capabilities, facilities, and expertise at U.S. Department of Energy (DOE) National Laboratories. Industry Partners will have the first opportunity to license technologies produced in the course of collaboration under a Cooperative Research and Development Agreement (CRADA). As part of Strategic Core Industry Partnerships, industry partners will provide funding or in-kind support in addition to industry perspective and expertise.

The ABF is a consortium of seven DOE national laboratories that operate as a distributed biofoundry in collaboration with industry and academia. We have worked with more than 30 partners developing biomanufacturing tools and processes to enable sustainable industrial production of renewable fuels and chemicals. Learn more about ABF capabilities and details on collaborations.

Interested in discussing your company’s biomanufacturing priorities and specific ABF capabilities? Please contact ABF Business Development Lead Jesse Colangelo at [email protected].

Key deadline: New projects must have a statement of work and budget established by Dec. 31, 2024.

The following ABF tools are available for Strategic Core Industry Partnerships (organized by Analysis, Host-onboarding, Design, Build, Test, Learn, and Scale):

Analysis

- Process modeling and techno-economic analysis: Quantify the impact research and development have on the economics of an integrated bioprocess. Understand critical factors in equipment design and operation, scale-up, and broader implications for integrating a bioprocess in an overall biorefinery context.

- Life-cycle analysis: Use the GREET® model to understand the environmental impact of a fuel or bioproduct from a supply chain perspective — from feedstock production to the final product. The results can identify the environmental benefits of bio-derived chemicals and fuels, and primary drivers and technical barriers along the supply chain.

Host Onboarding

- New Bacterial and Fungal Host Development: Rapidly develop foundational datasets and basic genetic methods required for rational strain development of non-model microbes with unique phenotypes that can be beneficial for biomanufacturing, to enable and enhance strain improvement.

- Genetic tool development: Apply a large — and growing — collection of genetic parts for engineering diverse bacteria and fungi, which can be rapidly adapted to new organisms.

- Host Onboarding Tool: A web application with current status of host development within the ABF, including capabilities established and progress through the tier system. Integrates with other related data repositories to make accessible experiment data, strains and sequences, and protocols associated with these microbial hosts.

Design

- Design through Machine Learning: Test only a small fraction of all possible combinations of synthetic biology parts, computationally infer the results for all others, and recommend optimal combinations.

- Computational Enzyme Design: Perform machine learning-based and structure-based selection and design of enzymes for gain-of-function.

- Pathway Development and Evaluation: Design of metabolic engineering and bioprocessing strategies to enable production of exemplary targets that can be converted into several bioproducts.

- DIVA bioCAD: A software platform that enables researchers to visually design (combinatorial libraries of) DNA for downstream construction.

Build

- DIVA DNA Sequence Construction and Validation: Physically fabricate and sequence validate DNA constructs of interest. Validation provides full NGS (no DNA oligos required) plasmid/amplicon sequence coverage.

- Genetic Tools for Bacterial Hosts: Strain engineering in non-model bacteria, including thermophiles, acidophiles, aerobes and strict anaerobes. Initial host onboarding to advanced genome engineering (high throughput SAGE recombination system and genome scale (RB-TnSeq and CRISPRi) technologies).

- Genetic Tools for Fungal Hosts: Genetic tool development and strain engineering in non-model fungi, including yeast and filamentous fungi.

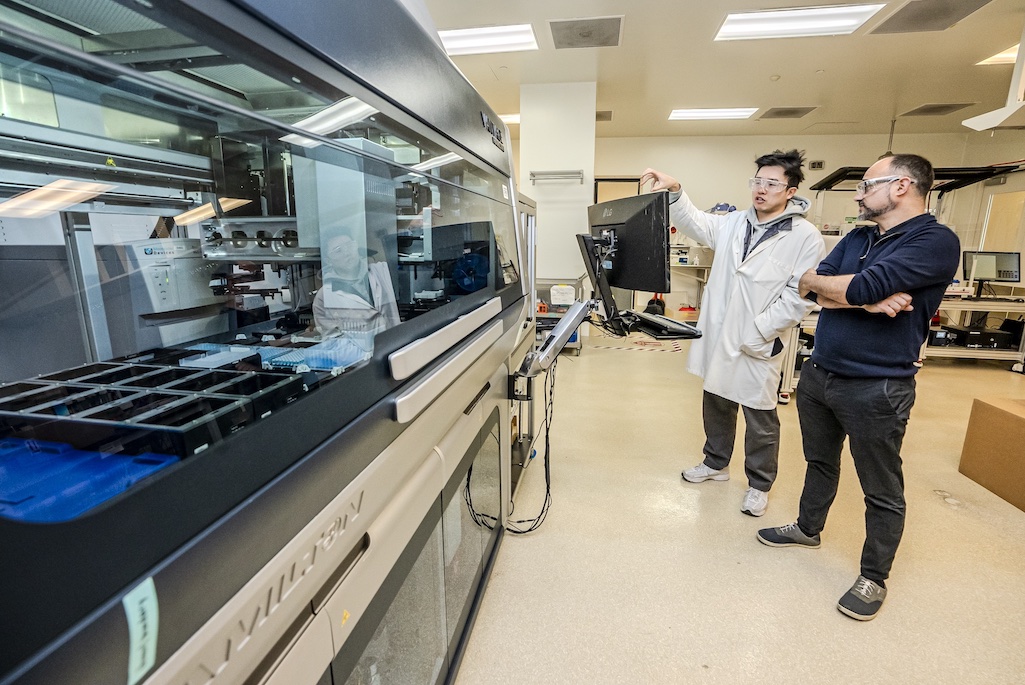

- Automated Workflows of transformation through genotype/phenotype screening targeting key bottlenecks in screening microbial colonies, in conjunction with genome-scale library approaches.

- Adaptive Laboratory Evolution

- Conventional: Serial transfer or chemostat cultivation in selective conditions , allowing beneficial mutations to arise and become more abundant in the population. Isolation and whole genome sequencing of superior performers.

- Droplet: HTP cell-based sensors for initial characterization of individual clones at microscopic scale.

- Flow Cytometry: Fluorescence-activated cell sorting (FACS) to sort microbial populations solely based on fluorescence.

Test

- Riboregulators for Precise Gene Expression Control: cis-repressor/trans-activator pairs to regulate expression of the gene from very low to near native levels; tuned standalone cis-repressors that completely repress expression.

- HTP Biocatalyst Optimization: A microfluidic platform to identify improved and/or missing catalysts in production pathways.

- HTP Proteomics: Targeted proteomics for accurately quantifying protein abundance, stoichiometry of protein isoforms and protein post-translational modifications. Determine pathway bottlenecks, compare enzyme homologs for specific enzyme steps, and track dynamic regulation of protein levels in engineered microbes.

- Targeted Metabolomics: High-resolution, high-mass accuracy mass spectra and structural information of metabolites as well as their absolute concentrations, using UHPLC-QTOF-MS and GC-MS.

- Discovery Multi-Omics: Global (untargeted) metabolomics, lipidomics and proteomics measurements to provide in-depth analysis of all metabolites, lipids and proteins present in the same sample by our well-established Metabolite, Protein and Lipid Extraction (MPLEx) protocol. These measurements provide rich data sources for pathway analysis and strain improvement.

- Biosensors

- FRET: Ligand-dependent protein conformational changes coupled to a ratiometric fluorescent signal response. Can be used intra- or extracellularly to provide rapid, real-time responses to ligands or metabolites of interest

- Transcription Factor: “Sense” and “report” accumulation of the target molecules (i.e., products of bioconversion); fluorescence signal correlates with the bioconversion efficiency and intracellular pool of the product.

- Structure Based Protein Design: Smart Microbial Cell technology that uses a custom-designed sensor-reporter system to screen for a given small molecule of interest.

- HTP MS Screening: Rapidly (5,000 assays/day) acquire quantitative mass spectra of target molecules as well as their absolute concentrations using a RapidFire-triple quadrupole mass spectrometric (RF-MS) system.

- HTP Thermostability Screening: of enzyme libraries for thermostability via direct expression in a thermophilic host at an elevated temperature. Protein expression and stability is estimated in situ using an anaerobic folding reporter that is stable at 65˚C, and is sensitive to the expression and folding of protein fused to it.

- Automated Robotic Pipeline for Enzyme Expression/Purification/Activity: Express, purify, and assay proteins and enzymes. Especially useful when purified proteins are required for quantitative assays, including to generate data for machine learning pipelines.

- Experiment Data Depot: A repository of experimental data and metadata, that provides a convenient way to upload a variety of data types, visualize these data, and export them in a standardized fashion for use with predictive algorithms.

Learn

- Mechanistic Models

- Pangenomic Analysis: Search tens of thousands of complete microbial genomic sequences for metabolic and regulatory mechanisms that can serve as solutions to biodesign problems.

- 13C Metabolic Flux Analysis: 13C Metabolic Flux Analysis (MFA) is the gold standard for measuring intracellular metabolic fluxes. Metabolite labeling is combined with experimentally measured extracellular fluxes to provide a “radiography” of internal metabolic fluxes.

- Genome-scale Metabolic Models: Predict strain manipulations that can improve the production of bioproducts of interest. Potential strain manipulations include reaction deletion, reaction addition, gene deletion or overexpression, and nutrient supplementation.

- Bayesian Metabolic Control Analysis: Kinetic models of microbial metabolism uses techniques from modern Bayesian inference, combined with an approximate kinetic rate rule, to make efficient inference of confidence intervals in enzymatic parameters.

- Artificial Intelligence

- Regulatory Deep Learning: Leverage microbial regulatory mechanisms for bioengineering processes, to optimize bioproduct production, mitigate stress responses that might lower yields, and more. By connecting microbes’ information processing and environmental sensing capabilities to the predictive computational design of regulatory networks, microbes become fully programmable biosystems.

- Kinetic Learning: Combines machine learning and abundant multi-omics data (proteomics and metabolomics) to effectively predict pathway dynamics in an automated fashion.

- Pathway Analysis and Multi-Omics Data Visualization: AgileBioCyc is a collection of organism-specific Pathway/ Genome Databases (PGDB) where each PGDB has been curated to include all the engineered pathways that have been designed for the organism. Use to interpret multi-omics measurements in the context of the metabolic and regulatory pathways of the host organism.

Scale Up

- Bioreactor Fermentation: Resolve the disparities between lab and commercially relevant scales of biomanufacturing. Once optimized at the bioreactor level, we conduct fermentations to generate the culture needed to optimize downstream recovery and purification operations. Multiple scales of systems available from 2-mL to 9,000-L, and access to over a dozen different downstream processing systems (in collaboration with the BETO-funded Separations Consortium).

–

A note on Transparency of Foreign Connections.

Parties interested in collaborating with DOE National Labs are subject to review for Foreign Connections. This review will include assessment of the following:

1. Any current or pending subsidiary, foreign business entity, or offshore entity that is based in or funded by any foreign country of risk or foreign entity based in a country of risk;

2. Any current or pending contractual or financial obligation or other agreement specific to a business arrangement, or joint venture-like arrangement with an entity owned by a country of risk or foreign entity based in a country of risk;

3. Any current or pending change in ownership structure of the Recipient or subrecipients that increases foreign ownership related to a country of risk. Each notification shall be accompanied by a complete and up-to-date capitalization table showing all equity interests held including limited liability company (LLC) and partnership interests, as well as derivative securities. Include both the number of shares issued to each equity holder, as well as the percentage of that series and of all equity on fully diluted basis. For each equity holder, provide the place of incorporation and the principal place of business, as applicable. If the equity holder is a natural person, identify the citizenship(s);

4. Any current or pending venture capital or institutional investment by an entity that has a general partner or individual holding a leadership role in such entity who has a foreign affiliation with any foreign country of risk;

5. Any current or pending technology licensing or intellectual property sales to a foreign country of risk; and

6. Any changes to the Recipient or the subrecipients’ board of directors, including additions to the number of directors, the identity of new directors, as well as each new director’s citizenship, shareholder affiliation (if applicable); each notification shall include a complete up-to-date list of all directors (and board observers), including their full name, citizenship and shareholder affiliation, date of appointment, duration of term, as well as a description of observer rights as applicable.

Should DOE determine the connection poses a risk to economic or national security, DOE will require measures to mitigate or eliminate the risk. DOE has designated the following countries as foreign countries of risk: Iran, North Korea, Russia, and China. This list is subject to change.

Recognizing the disclosures may contain business confidential information, subrecipients may submit their disclosures directly to DOE.